Protect your revenue with trade-approved weighing and dimensioning technology.

Whether shipping goods by road, air or sea, having accurate weight and dimension data is vital to charging correctly and protecting profitability. The Express Freight Revenue Protection solution from Avery Weigh-Tronix offers a unique and effective way of capturing freight dimensions and weight while minimising manual capture and input. As the first mobile weighing and dimensioning solution on the market, it provides significant time and cost saving versus manual alternatives.

Speak to one our experts to help you find the most effective solution for your sector.

Contact Us-

BMC Concrete Deck Weighbridge

Read moreTrade approved weighing up to 100 tonnes with improved surface traction and rust/corrosion protection

-

BridgeMont Steel Deck Weighbridges

Read moreVersatile, dependable, long-lasting scales with unbeatable structural integrity and cost effectiveness

BridgeMont steel deck weighbridges are available in a wide range of standard lengths and widths or can be custom built to your specifications.

-

BS Diamond base Series Bench Scale Bases (45kg-250kg)

Read more5000d legal for trade Single loadcell bench or floor base. Robust, accurate & very reliable, available in both carbon steel or food grade stainless steel, NSF approved for food areas, IP69K easy to clean. Ideal for warehouse or food manufacture, normally combined with an Avery Weigh-Tronix Indicator

-

BSG Torsion Bench Scale Base (3kg-30kg)

Read more3000d legal for trade Single loadcell torsion bench base. Robust, accurate & very reliable, 500% shock load protection available in food grade stainless steel, NSF approved for food areas, IP69K easy to clean. Ideal for warehouse or food manufacture, normally combined with an Avery Weigh-Tronix Indicator

-

BSQ High Resolution Digital Bench Base (1kg-80kg)

Read more10,000d legal for trade robust digital bench base, balance performance that can be used in a harsh industrial environment. Over 1100% overload protection, 1 billion internal counts that can provide a stable weigh reading at 1 Million divisions. Normally connected up to an Avery Weigh-Tronix weight indicator, PC or ZK counting scale

-

CHEKLODE PT300 Axle Weigh Pads

Read moreSelf-Contained Portable Axle Weighing System.

Wirelessly connect up to 8 weigh pads to obtain total vehicle weight.

-

DataPower

Read moreTrack raw materials into production and waste output to identify inefficiencies

-

Fixed Axle Weighing System

Read moreWeighbridge style, high accuracy, in-motion axle weighing.

Weigh any vehicle up to 40,000 kg per axle.

-

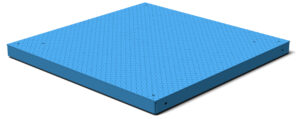

H407 General Purpose Floor Scale

Read moreHard wearing steel floor scale suited for everyday weighing in industrial settings.

Designed to withstand the rigours of everyday wear and tear when loading and unloading with fork trucks, pallet trucks, and wheeled bins.

-

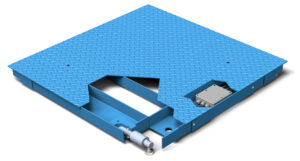

H506 Ultra Low Profile Floor Scale

Read moreSuited for everyday weighing in industrial or airport settings.

-

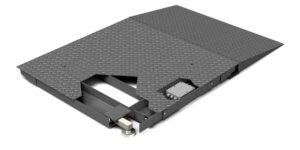

H520 Heavy Duty Floor Scale

Read moreThe H520 heavy duty steel floor scale is designed for constant use in tough industrial environments. This platform scale features patented Weigh Bar technology.

-

H530 Stainless Steel Floor Scale

Read moreSuitable for heavy washdown or other harsh industrial environments.

-

LS630 Portable Axle Weighers

Read morePortable in-motion axle weighers

-

MaxDec High Capacity Floor Scale

Read moreThe MaxDec heavy duty floor scale is designed for high traffic and high capacity weighing up to 100,000 lbs.

-

Pallet Truck Scales

Read moreRobust, accurate weighing on the move

-

Printers

Read moreWe offer a range of printers to complement your weighing system and meet the precise needs of your operation.

-

Remote XR Display

Read moreAvery Weigh-Tronix remote displays allow clear, comfortable viewing of scale information at considerable distances, indoors and outdoors.

-

Unmanned Weighbridge Terminals

Read moreAllow drivers to complete weighing transactions 24/7 without leaving their vehicle

-

Weighman 8 Weighbridge Software

Read moreTotal management reporting and control of your weighbridge operation, across one or multiple sites.

-

ZK830 High Resolution Digital Counting Scale

Read moreThe most accurate counting scale on the market.

-

ZM201 Series Indicators

Read moreZM201 Series indicators are ideal for applications that require a basic weighing indicator for performing Zero, Tare and Print functions

-

ZM305 Multi-Function Weight Indicator

Read moreThe ZM305 Standard weight indicator is ideal for floor scales, batching, vessels and for in motion conveyors.

United States

United States  Canada

Canada  Canada (fr)

Canada (fr)  India

India  Malaysia

Malaysia  Ireland

Ireland