Guide: Weighing in a Warehousing and Logistics Environment

Warehousing and distribution centers rely on efficient and reliable data to ensure peak performance, without compromising on safety. Scales and systems from Avery Weigh-Tronix can help ensure billing is accurate by monitoring cargo weights, tracking data and ensuring vehicles are filled to the optimum safe capacity.

Our products simplify compliance with health and safety codes. They also maintain efficiency throughout your organization to control costs and protect profits. Regardless of the application, correct weighing practices—including choosing the appropriate scale system—can increase revenue. Integrating weighing into warehouse operations improves shipping and billing accuracy and improves overall production.

Legal-for-trade weighing

A scale system capable of legal-for-trade weighing can prove to be a valuable asset in the logistics industry. This is because revenue is normally based upon the weight of purchases made by or shipped for customers. Legal-for-trade accuracy is required for business deals where goods are bought or sold by weight. Avery Weigh-Tronix provides a wide range of legal and non-legal scales. The benefits of a legal-for-trade system extend beyond legality into a scale system that provides reliable, repeatable weighing of goods ensuring customer satisfaction, precise billing and accurate inventory records.

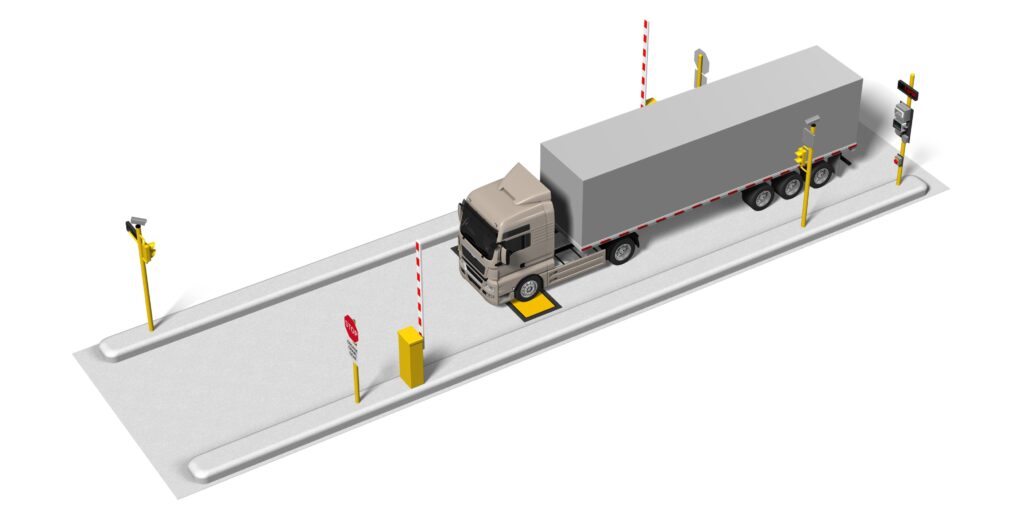

Vehicle Scales

Properly managing inventory and billing in warehouse and distribution center environments depends on two things. Namely, recording and weighing both inbound and outbound freight. With the high cost of fuel, bulk carriers have to balance the need for optimal loading with concerns about safety. Truck scales, weighbridges and axle weighing systems from Avery Weigh-Tronix will help ensure trucks are loaded to the ideal weight. They also ensure they conform to strict legal maximum-weight regulations. Accurate weighing helps companies avoid costly fines as well as vehicle wear due to over loading.

For extra efficiency, truck scale or weighbridge controls may be integrated into a standalone console. This allows for unattended weighing operations. The terminals enable drivers to complete weighing transactions 24/7, without leaving their cab. The result is that your truck scale can run without a dedicated operator. This then results in reduced operating costs, more hours of availability and better health and safety by allowing the driver to stay within their vehicle.

Floor and Platform Scales

Used mainly at goods in/out or when sorting inventory, floor scales are capable of weighing goods with very high accuracy, reducing the likelihood for revenue loss. In fact, this scale system can be placed at a central location within a warehouse and is normally used in two ways. Operators can wheel lighter loads onto the scale for weighing. For heavier loads, operators can then drive forklifts carrying bundled or palletized goods directly onto the scale.

Digital Weight Indicators

On a basic level, weight indicators collect, store and communicate weight data. As such, more advanced digital indicators use wireless communications to send data to back office systems. This improves management information and control and producing instant, accurate invoices for all materials weighed. Further, these indicators can be linked to printers, barcode scanners, computers and other systems for integration into existing networks, allowing easy data transfer and management from anywhere in the operation.

Counting Scales

Counting scales are ideal for use in inventory control and for efficiently and accurately counting a high volume of the same parts. Our precision counting scales can all weigh even the smallest parts. This is done with an accuracy of over 99%, minimizing the operator error often found when hand counting. The counting scale range is tough enough to take on any industrial environment and can handle overloading and shock loading while counting quickly and accurately.

Forklift Scales

A forklift scale allows drivers to lift and weigh bundled materials on the truck. This expedites operations by enabling forklift drivers to take commodities directly to storage upon delivery, while tracking the weight, origin and storage location during transport. This process results in real-time data acquisition, which can be used for billing and inventory management. The ability to transport and weigh materials in one simple step results in tremendous time savings and a speedy return on investment. Forklift scales are also a compact weighing solution, making them suitable for the busy warehousing environment. In-cab instruments such as bar code scanners allow forklift operators to instantly capture all necessary freight data available, then transmit this information with weight data wirelessly via Bluetooth® or radio to supervisory computer systems.

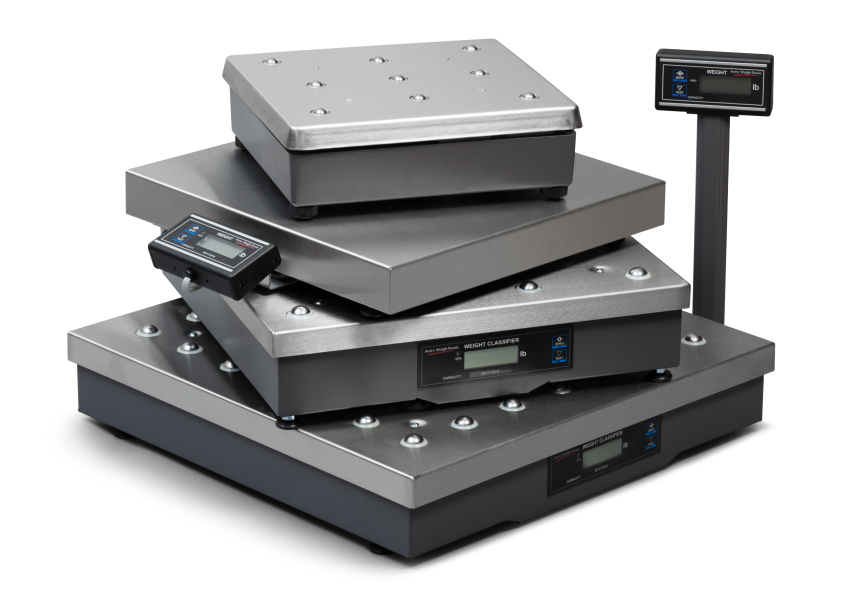

Bench & Shipping Scales

Suited to weighing smaller packages, bench and checkweighing scales are ideal for basic weighing, checkweighing and counting applications. They are available in a range of sizes, capacities and finishes and designed with a small footprint to maximize work space. When it comes to shipping parcels, the ability to correctly charge by weight, capture data and integrate with existing systems can impact profitability. Avery Weigh-Tronix postal and parcel scales interface easily with existing shipping, mailing and inventory systems for efficient and accurate processing.

Software

Avery Weigh-Tronix scales can be paired with sophisticated software and indicators to provide additional data collection, tracking and analysis. Software innovations help to facilitate efficient documentation and management of key weight, commodity and scale data. Whether you need a simple data capture package collecting weight information from a vehicle, or an integrated management system monitoring operations in real-time, we can supply a standard or tailor-made solution to suit.

Service, Calibration and Scale Maintenance

Having a trusted and reliable service supplier can keep your business moving and maximize ‘up-time’. We are committed to providing high quality, lifetime service support for all of our weighing equipment. Avery Weigh-Tronix is supported by a global network of dedicated service technicians on hand to install and maintain your equipment, including regular calibration, servicing and repair.

United Kingdom

United Kingdom  Canada

Canada  Canada (fr)

Canada (fr)  India

India  Malaysia

Malaysia  Ireland

Ireland