One of the primary reasons that logistics vehicles are weighed is to avoid overloading. Federal vehicle weight limits were put in place to protect the highway system. Overweight or unevenly loaded vehicles cause greater wear and tear on roads and highways, as well as posing a danger to bridges and other infrastructure.

Regulations and laws governing truck weights are a blend of federal and state laws. Federal law controls maximum gross vehicle weights and axle loads on the Interstate System. According to federal law, gross vehicle weights must not exceed 80,000 lbs, axle weights must not exceed 20,000 lbs, and there is a weight limit of 34,000 lbs for tandem axles.

The simplest way to check the weight of vehicles is to use a truck scale. For logistics companies that operate large fleets, pairing truck scales with indicators, traffic lights, barriers, and software can create a fully automated traffic management system.

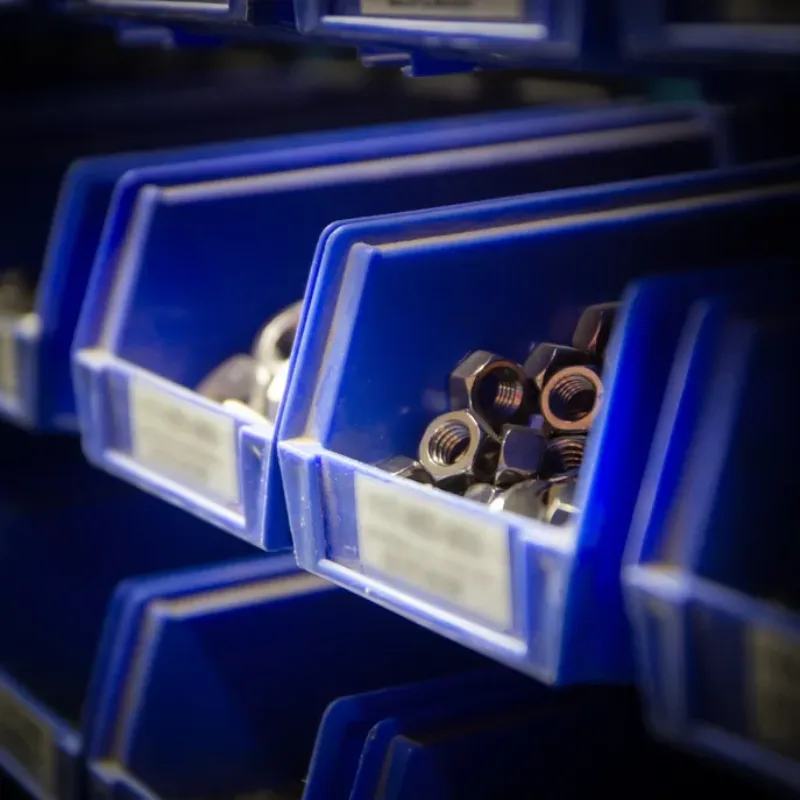

Forklift scales can also be used to weigh goods during loading, allowing operators to ensure that trucks are loaded evenly.