Weighing scales, truck scales, and train weighing systems are used to accurately measure incoming metals and other raw materials, ready for fabrication. This ensures the metal fabrication plant is paying for and using the correct raw materials. As well as protecting revenue and optimizing cost control, weighing incoming goods can also help with materials traceability and inventory control.

Scales and weighing systems for metal fabrication.

Metal fabrication is an important part of the manufacturing industry. Metal fabricators play a key role in producing components and structures for a wide range of applications, from automotive and aerospace to construction and consumer goods. Metal fabricators need to measure high-value incoming raw materials, completed goods, and waste carefully in order to minimize costs and guarantee operational effectiveness.

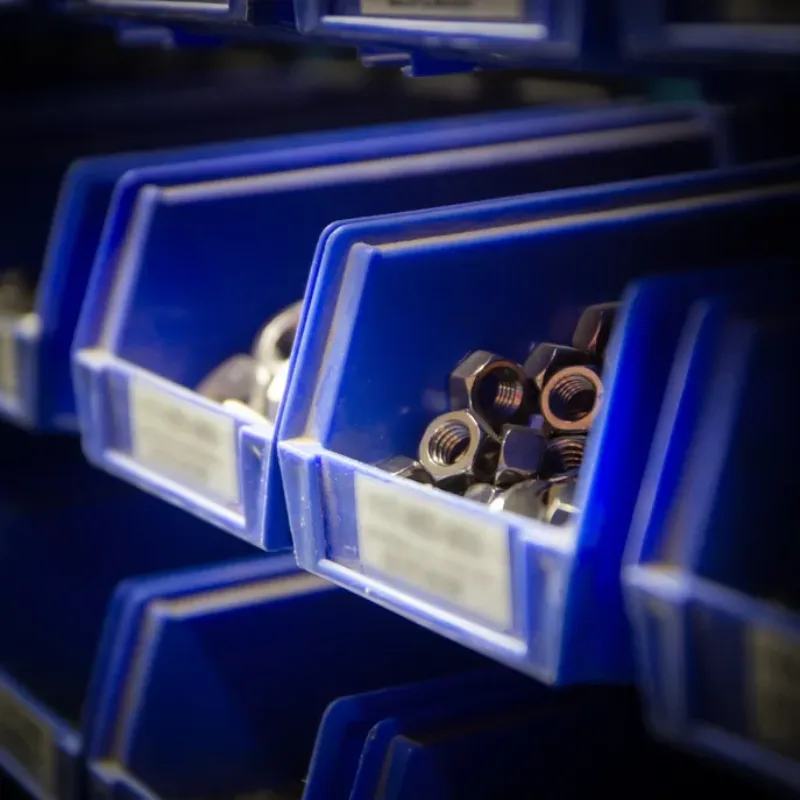

Weighing systems are used in fabrication to maintain strict quality control, run metallurgy tests, and mix precise recipe formulations. Often, weighing systems are paired with sophisticated software and indicators to form a complete weighing and data analysis system that can record and evaluate data.

For this industry, scales and weighing systems need to be durable enough to endure harsh conditions and provide consistent performance with little maintenance downtime.

Heavy duty train weighing systems and floor scales can be fitted under rail track to weigh carts of raw materials or finished products such as coils or blocks of metal. Train weighing systems can also be used to optimize the coking process and ensure the furnace is operating at maximum efficiency.

Metal fabricators use lab balances and highly accurate bench scales to uphold quality control procedures by running metallurgy tests or using them to measure raw ingredients when mixing formulations.

Reporting of waste in metal fabrication is a critical aspect of managing the environmental impact of operations and ensuring regulatory compliance. By gathering data about waste, including weight data, metal fabricators can track their waste generation, implement reduction strategies, and comply with legal requirements.

Truck scale controls can be integrated into a standalone console that allows weighing operations to continue unattended. This means drivers are able to complete weighing transactions 24 hours a day without leaving the cab. The result is a truck weighing system that runs efficiently for extended hours, without a dedicated operator – reducing labour costs, improving traffic management on site and ensuring compliance with vehicle weight legislation.

Solutions for Manufacturing

Find a weighing equipment supplier near me

We work with a network of reliable and trusted distribution partners to ensure that we can offer a truly personal, local service, wherever you’re located.