Overview

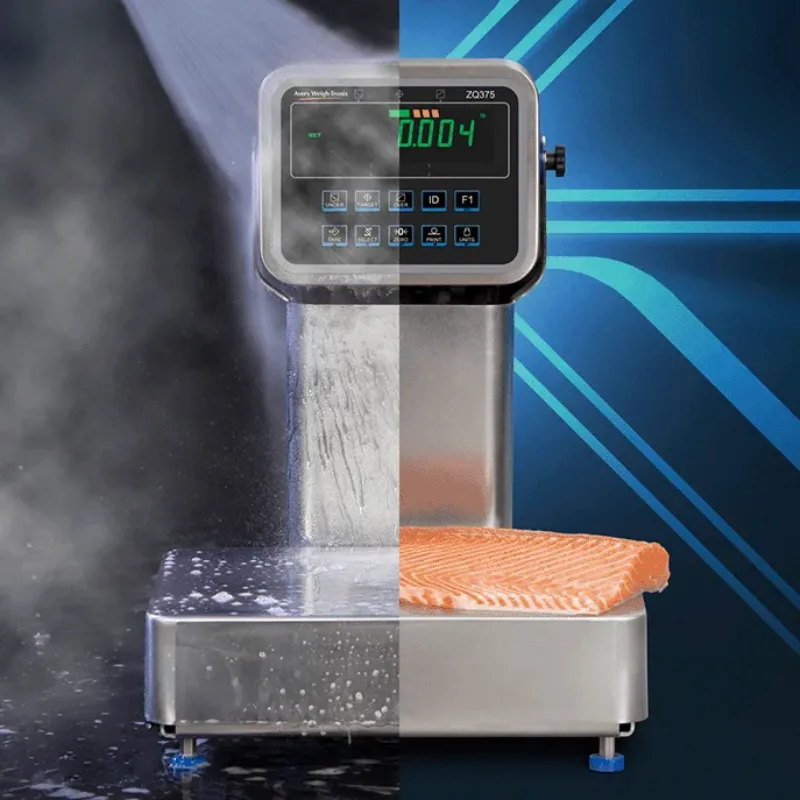

Quaker Houghton, a producer of fluid technology products is achieving yields of around 99.9% thanks to vessel weighing equipment from Avery Weigh-Tronix.

The company chose a load cell system to measure the contents of 24 blending vessels and a new recipe weighing system to semi-automate the blending of products.

Previously, the company relied on flow meters to monitor the charging of bulk liquids from 36 storage tanks to the blending vessels, with operators manually opening valves to discharge each ingredient. This produced inaccurate results and resulted in laboratory rework to bring products up to specification.

“Fitting load cells to all our blending vessels has been an ongoing major improvement project. The new system has been installed alongside the previous equipment and has been completed without closing down our production,” comments Tony Powell, Production & Warehouse Manager at Houghton Trafford Park.

Invaluable knowledge and expertise

“The input and knowledge of Avery Weigh-Tronix process weighing specialists has been paramount to us in choosing the correct system. Avery Weigh-Tronix was one of three companies given the opportunity to quote for the work and from the results we are achieving, I am confident it was the right choice.”

Benefits:

- Load cell weighing produces totally accurate results -helping the production area to improve ‘Right First-Time’ targets and increase correct yields.

- Semi-automating the blending operation reduces errors and controls wastage.

- The system generates production information which contributes to traceability and quality control procedures.