Overview

Weigh Bars and indicators provide durable, virtually replacement-free operation after more than a dozen years in use, withstanding heavy loads and harsh environmental elements.

As the need for oil increases, so does business in the drilling industry. M-I SWACO, based in Houston, USA, distributes two important materials for this industry: Barite, a cement-like casting material that keeps soft, sandy earth from caving in during the drilling process; and a gel material, mixed to customer specifications, which allows a bit to drill more efficiently.

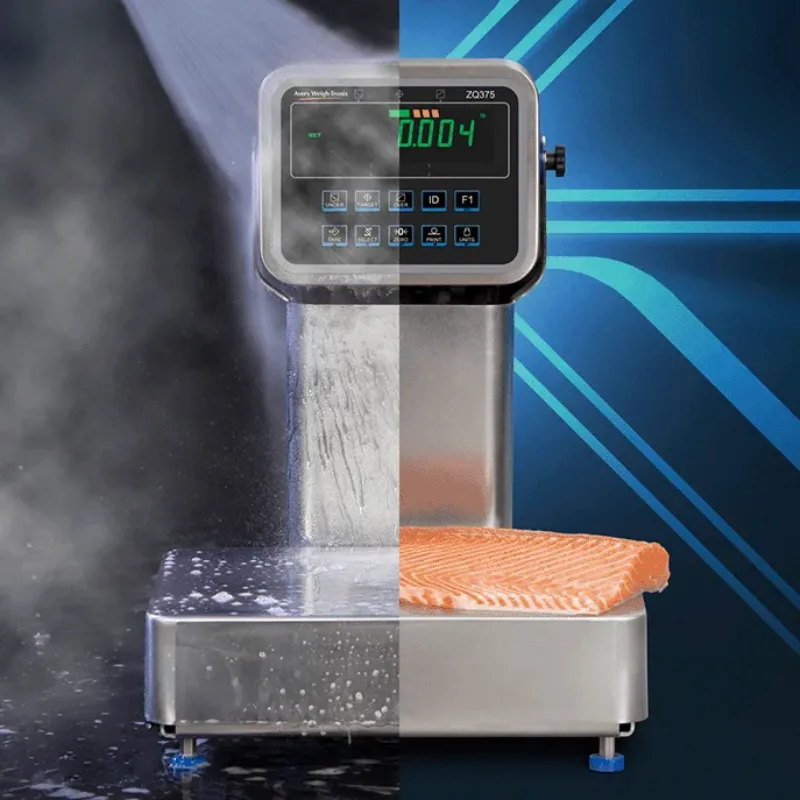

Heavy Duty, Durable and Reliable

Weighing these materials to meet customer requests, however, poses several challenges. Barite, stored in tanks weighing up to one million pounds each, is transported from a chemical vendor via an ocean faring barge. Tank size has increased significantly over the years to reduce the time that was previously spent refilling smaller holding tanks. Upon the barge’s arrival, each of these tanks must be weighed. Then, the Barite is pumped into a weighing tank in order to measure out the customer’s requested amount. In order to perform accurately over an extended period of time, the scales used in such an application must be heavy-duty to withstand regular weighing of million-pound loads, yet durable enough to withstand the rain, salt water, humidity and other environmental challenges of an offshore location.

Multifaceted System

When gathering chemicals for their gel product, M-ISWACO faces the additional challenge of weighing several components used to make up the material. Depending upon the customer’s requirements, anywhere from three to five chemicals are taken from their respective transport vessels, weighed and pumped into a single tank. The resulting product is then weighed in full and sent to the customer. This process requires not only a rugged scale, but also a multifaceted system for keeping track of the different materials in use.

To solve this complex application, M-I SWACO approached local distributor G.T. Michelli to devise a robust, multipurposed scale system. The solution included 35 separate systems, each requiring four (4) 250K batching Weigh Bars and highly accurate indicators from Avery Weigh-Tronix.

“Since the application is taking place on the Gulf Coast and in the harsh elements, M-I SWACO needed a scale with high reliability to stand up to the challenge,” said Mark Vicknair, regional manager at G.T. Michelli.

The Weigh Bar

“Avery Weigh-Tronix’s Weigh Bars are durable and long lasting, designed to withstand this kind of environment.” To weigh the Barite material, four 250K Weigh Bars are used to make up a scale with a one-million-pound capacity. These bars are used to weigh the chemical elements of M-ISWACO’s products.

“This arrangement allows M-I SWACO’s customers to take the maximum amount of Barite out to the oil rig in one trip,” Vicknair said. “With a million-pound tank, you can pump out a customer’s entire order of Barite at once. It’s like a gas station—though the process takes several hours due to the large amounts of product involved, a boat can simply go in and out of the weighing area without returning for multiple product batches. This saves time and money; while making sure the client gets the right amount of the product they order.”

Minimum Maintenance, Minimum Downtime

“The Avery Weigh-Tronix equipment is high-quality and requires little maintenance, which reduces production downtime,” said Jose Herrera, facilities manager at M-ISWACO. “The service G.T. Michelli provides is excellent—we just pick up the phone, and they’re available to help us.”

After more than a dozen years in use, the Avery Weigh-Tronix scale system has delivered exceptional performance with few failures. This durable, convenient solution has allowed M-I SWACO to keep up with their customers’ increasing business requirements efficiently and cost effectively.

“The reliability of Avery Weigh-Tronix’s equipment has saved them a lot on replacement costs,” Vicknair said. “After more than a decade in operation, the equipment has needed next to none.”