Safety is at the heart of our business culture and as a result we are dedicated to ensuring the safety of our employees and of our customers when completing service visits. We work to detailed risk and method statements (RAMS) for every job which have been scrutinised by our Health and Safety team and continually improved as we work to reduce risk across our operations. We empower our employees to make a call on safety and we support them to walk away from any job they deem unsafe, until the risk has been removed. Where there are higher risks, such as pit-mounted weighbridge installations, we will send a team of three engineers to ensure we meet our high safety standards for confined space jobs and minimise any potential risk.

Why choose Avery Weigh-Tronix?

As the leading national provider of industrial weighing equipment service, repair and calibration services, Avery Weigh-Tronix are equipped to support businesses of all sizes to ensure they meet legislation and stay compliant with their weighing systems.

We offer transparent service agreements with Silver, Gold and Diamond cover options from all-inclusive to more cost-effective agreements, all offering a comprehensive service. We make it easy to choose the right plan for your operation and are transparent with what’s included so won’t get any unexpected charges.

Avery Weigh-Tronix are authorised by NSAI as a government approved supplier and verifier of weighing equipment in Southern Ireland. Our services span standard calibrations and full reverifications for weighbridges and other weighing equipment.

We take a lifecycle management approach to servicing and maintaining customer equipment which reflects our desire to build long term relationships with our customers. Our focus on preventative maintenance keeps your equipment working at maximum efficiency and reduces the likelihood of costly emergency breakdowns. Our highly trained service engineers will work with you to identify potential issues before they arise. This then ensures that your equipment is always running reliably and accurately.

We have an extensive network of 100 service engineers located across the UK and Ireland which means your local engineer is never more than 26 minutes away. Our site dedicated engineers will get to know you, your equipment and your operation to offer the fastest response and maximise uptime. To speak to one of our team our Service Experience Centre operates 365 days a year where our friendly team of service advisors will ensure you are dealt with quickly in emergencies and will offer any additional support you may need with your equipment or service visits. Our fleet of 8 weighbridge test units allow us to provide the fastest weighbridge verification in the UK and Ireland, meaning your equipment can be repaired and back in operation with minimal business disruption.

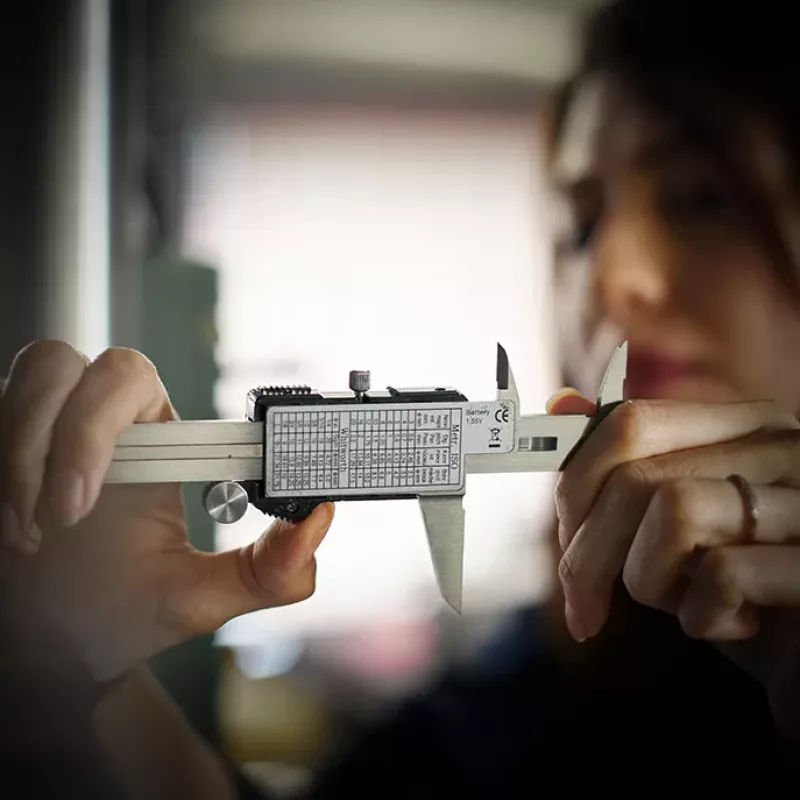

In addition to weighing equipment, our expert technicians are available to visit your premises and calibrate other measurement equipment on-site including torque, pressure, temperature and hand-tool devices. We understand how vital it is to keep your equipment calibrated for audit and compliance purposes. But we also know how difficult it can be to remove those items from your process for them to be calibrated and maintained effectively when your tools aren’t on-site. Our on-site calibration service is designed to reduce downtime, reduce costs, and minimise disruption.

Our team of experienced engineers will perform a comprehensive calibration service on your instruments using a range of state-of-the-art testing tools. Any discrepancies found can be adjusted to reflect your measurement specifications, ensuring you’ve got the tools to do business as accurately as possible. Our mobile technicians use the same state of the art equipment that would be used in a laboratory when carrying out on site calibrations. The team arrive fully qualified and equipped to bring you the same quality and accredited calibrations you’ll get from a laboratory service, to fully traceable standards.

Avery Weigh-Tronix works to the highest international standards, meaning that every piece of equipment entering our laboratory undergoes rigorous checks by fully qualified engineers. We provide standard traceable and UKAS accredited testing and calibration services, removing the risk of inaccurate measurements, product failures and accidents.

You can access calibration certificates, service visit reports and covered assets via our online portal which is available whenever you need it. You can find out more about our accreditations on our Calibration and Testing page.

Unbeatable Response Times

We have an extensive network of 100 service engineers located across the UK and Ireland which means your local engineer is never more than 26 minutes away. Our site dedicated engineers will get to know you, your equipment and your operation to offer the fastest response and maximise your product uptime. Our Service Experience Centre operates 365 days a year where our friendly team of service advisors will ensure you are dealt with quickly in emergencies and will offer any additional support you may need with your equipment or service visits. Our fleet of 8 weighbridge test units allow us to provide the fastest weighbridge verification in the UK & Ireland, meaning your equipment can be repaired and back in operation with minimal business disruption.

Compliance at the Core

Avery Weigh-Tronix is accredited to the highest international and national standards, meaning that every piece of equipment entering our laboratory or serviced undergoes rigorous checks by fully qualified engineers.

We provide standard and UKAS accredited testing and calibration services, removing the risk of inaccurate measurements, product failures and accidents.

You can access calibration certificates, service visit reports and covered assets via our online portal which is available whenever you need it. Find out more about our accreditations on our Calibration and Testing page.

.

Our Safety Promise

As an ISO 45001-accredited business, safety is at the heart of our culture and as a result we are dedicated to ensuring the safety of our employees and of our customers when completing service visits. We work to detailed risk and method statements (RAMS) for every job which have been scrutinised by our Health and Safety team and continually improved as we work to reduce risk across our operations. We empower our employees to make a call on safety and we support them to walk away from any job they deem unsafe, until the risk has been removed. Where there are higher risks, such as pit-mounted weighbridge installations, we will send a team of three engineers to ensure we meet our high safety standards for confined space jobs and minimise any potential risk.