For larger ingredients handling operations, weighbridges are an ideal solution for weighing and monitoring loads coming into and out of a site. Paired with traffic management systems – including barriers, traffic lights, and cameras – weighbridge systems can help to control traffic flow, prevent accidents, and monitor and record incoming and outgoing loads effectively. For busier sites or those that run 24-hour operations, unmanned weighbridge systems can extend operating hours without additional manpower.

Overview

Bulk weighing is the process of accurately measuring large volumes of raw materials – such as grains, aggregates, powders, and liquids – typically during the loading or unloading of vessels like hopper trailers, cargo ships, or rail wagons. It plays a critical role in industries such as agriculture, mining, construction, and manufacturing, where high-throughput material handling is standard. Precision in bulk weighing is essential for inventory control, process optimisation, regulatory compliance, and commercial accuracy.

However, weighing at speed and scale introduces operational challenges. Inaccuracies can result in overfilling, product giveaway, shipment overloads, and bottlenecks in throughput – all of which impact profitability. Manual processes or unreliable equipment can add to labour costs and reduce operational efficiency.

Avery Weigh-Tronix’s advanced bulk weighing solutions offer robust, accurate, and automated control. Our solutions such as weighbridges and vehicle weighing systems help monitor incoming and outgoing loads, while floor scales, platform scales, and load cells fitted to silos, hoppers or tanks ensure precision during filling. Integrated systems enable real-time feedback, data capture, and centralised control – reducing waste, improving consistency, and increasing productivity across the supply chain. With the right weighing technology, businesses can turn a historically manual and error-prone process into a source of operational and financial advantage.

Weighbridges provide the perfect vehicle weighing and traffic management solution at site entrances and exits, allowing user to manage and monitor incoming loads. By attaching load cells to a tank, silo or hopper, the weight of the stored bulk ingredients can be captured and used for inventory management.

Ingredients often represent a significant portion of overall production costs. Accurate weighing helps to monitor ingredient usage, minimise waste, and reduce costs.

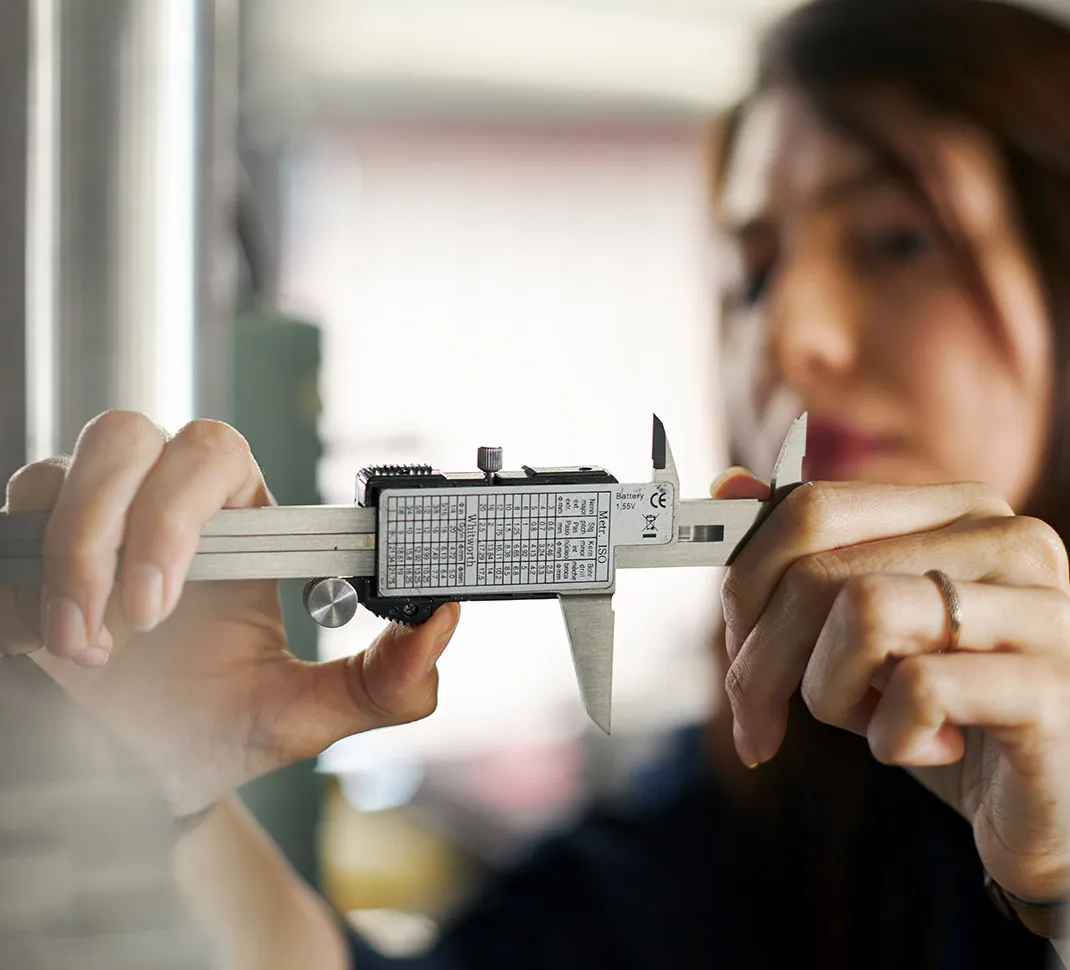

For ingredient measurement in recipe formulation applications, using weight sensors and indicators together can improve accuracy and product consistency.

Combining load cells and indicators can create a weighing system that stores recipe components and ensures precise dispensing of each ingredient.

Using weighing equipment in complex blending, batching or recipe formulation applications, can improve quality control and inventory management, reduce labour and rework costs, and reduce product giveaway.

Some bulk ingredient processing sites will also break their finished products down into smaller packages for re-sale to the end-customer. Avery Weigh-Tronix offers a range of scales, including bench, floor and static checkweighing systems, which can be used for quality checks, to meet average weight legislation requirements, or for onward shipping.

Avery Weigh-Tronix offers a range of ATEX-approved weighing and process automation for use in hazardous environments. Our highly skilled service team are fully trained to handle ATEX equipment and ensure ongoing compliance.

When downtime is not an option, Avery Weigh-Tronix scales are the perfect solution. Reliability is key when dealing with large quantities of ingredients or shipping finished goods. We build our floor, bench, and vehicle scales to withstand daily use in bulk ingredient handling applications.

ZM Applications to Transform your Operations

Transforming your Operation with the ZM Bulk Weighing Application

Powered by our ZM510 and ZM615 Weight Indicators, our ZM bulk weighing application is engineered to optimise the performance of automated bulk filling processes across a range of industries – from agriculture and aggregates to manufacturing and logistics. Designed for fast, accurate and reliable operation, it delivers real-time feedback, intelligent process control, and powerful data capture, enabling your team to reduce waste, maximise throughput, and make informed decisions.

From monitoring total throughput and controlling surge hoppers, to managing each fill with fast and slow options for greater accuracy, the system adapts effortlessly to your existing infrastructure and is simple to install with minimal disruption or cost. Operators benefit from a user-friendly interface and centralised control, while managers gain access to granular performance data that drives smarter, more efficient operations.

Our high performance, multi-function indicators are at the heart of our applications, providing the flexibility to adapt to your operational requirements and are suitable for a wide variety of applications including dusty, wet or high pressure and heavy washdown environments. The ZM510 and ZM615 can display, analyse, store and transmit data across a range of technology methods to meet your specific installation needs.

ZM510 / ZM615 Bulk Weighing Application Video

Key Features for Precision, Efficiency, and Control

Key Features:

-

Throughput Mode: Monitor total product received or dispatched across shifts for full visibility of plant performance.

-

Dynamic Process Control: Live feedback ensures accurate, seamless filling of grains, powders, or raw materials.

-

Optimised Tip Calculation: Calculates and adjusts tips to dispense the exact required volume – minimising waste and boosting efficiency.

-

Surge Hopper Control: Maintains continuous operation to eliminate costly downtime from material flow interruptions.

-

Fast and Slow Fill Options: Enhance accuracy without compromising throughput speed.

-

Cost-Effective Installation: Quick to deploy and easily integrated with existing systems – delivering a fast ROI.

-

Centralised Control Interface: Simplifies operation and monitoring from a single screen.

-

Comprehensive Data Capture: Detailed reporting on tip weight, errors, throughput, and cumulative performance when connected to a PC.

Whether you’re aiming to streamline operations, increase accuracy, or reduce material loss, the ZM bulk weighing application provides the tools to take control of your process – and your bottom line.

Products for Bulk Weighing

Compare Products

Contact Us

For free quote and consultation, speak to one of our experts today