Overview

Maximise Throughput and Profits with Our Precision Bulk Weighing Application

Are inefficient and inaccurate bulk weighing processes costing you time and money? The ZM Bulk Weighing Application is designed to meet the escalating demands for accuracy and efficiency in bulk material handling operations.

What is Bulk Weighing?

Bulk weighing refers to the process of measuring the weight of materials in large quantities. It is commonly used in industries where products are handled, stored, or transported in bulk, such as agriculture, mining, construction, and manufacturing. In bulk weighing, raw materials such as grains, aggregates, powders and liquids are typically loaded or unloaded in large quantities into large vessels such as train wagons, cargo ships and hopper trailers. During the filling process, accurately determining the weight of these materials is important for inventory management, quality control, billing, and process optimisation.

The Challenges Faced in Bulk Material Processing:

Weighing large quantities of raw materials at speed, during the filling processes, can often lead to challenges that can cause inefficiencies in your processes and lead to less profitable transactions. Inaccurate weighing can lead to product giveaway due to overfilling, overloaded shipments, slower operational throughput and additional human resources required, to name but a few.

Transforming your Operation with the ZM Bulk Weighing Application from Avery Weigh-Tronix:

Our ZM Bulk Weighing Application, has been designed to meet the challenges faced in industries where bulk weighing is a critical part of operations. With escalating demands for accuracy and efficiency in bulk material handling, the ZM Bulk Weighing Application is engineered for precise bulk weighing to a target weight, ensuring every shipment meets the exact specifications, enhancing your reputation for quality and reliability.

How it Works:

Throughput Mode:

Gain a comprehensive overview of your plant’s performance. Monitor the total product received or dispatched over a period, empowering you to manage shifts effectively and optimise operational efficiency.

Dynamic Process Control:

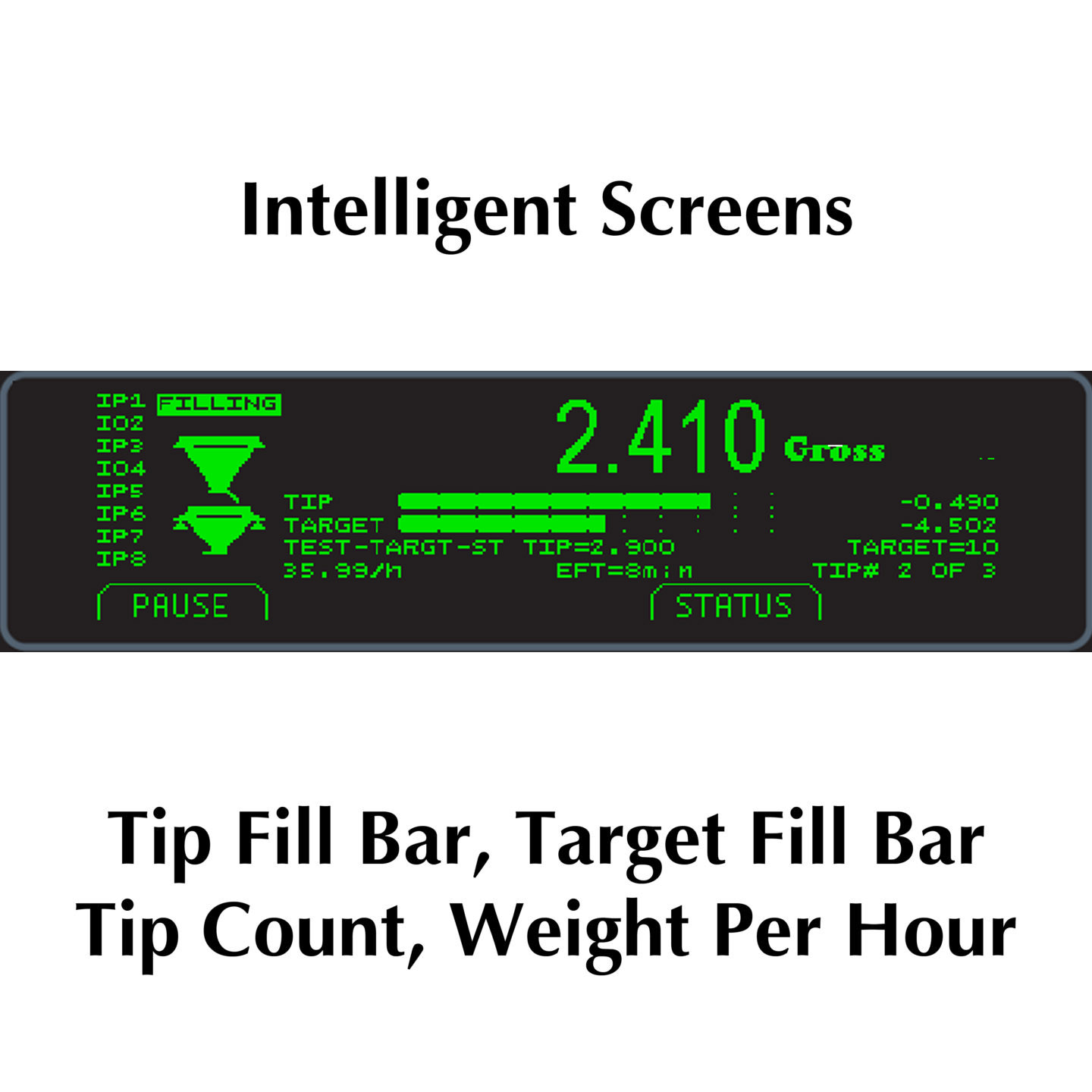

Loading grains, aggregates, powders, or raw materials? Our application provides live feedback to operators, pinpointing the filling process’ status with unparalleled accuracy, ensuring seamless operations and minimising downtime.

Optimised Tip Calculation:

Maximise efficiency and minimise waste with our intelligent Tip Calculation feature. Our application calculates the exact number of tips required to fulfill large bulk orders, adjusting each tip to dispense the precise amount of material, saving resources and boosting profitability.

Throughput Monitoring:

Gain quick and comprehensive insights into throughput with our application. Track and monitor throughput in any automated bulk filling process, enabling proactive decision-making and enhancing productivity.

Surge Hopper Control:

Surge hopper control keeps your weighing process continually running as any break in your material flow is wasted time and money!

Fast and Slow filling options:

Helps to improve accuracy of your filling process, while maximising throughput.

Cost-Effective Installation:

Fast, flexible, and simple to install within existing bulk filling systems, our application saves valuable time and resources with minimal capital expenditure, ensuring a swift return on investment.

Centralised Control:

Manage the entire automated bulk weighing process from a single, user-friendly interface. Our application streamlines monitoring and control, enhancing operational efficiency and simplifying management tasks.

Valuable Data Capture:

Unlock actionable insights with comprehensive data capture. When linked to a PC, our application provides detailed information on completed tips, tip weight, errors, cumulative weight, and hourly throughput, empowering data-driven decision-making and continuous improvement.

Indicators:

Our Bulk Weighing Application is powered by the Avery Weigh-Tronix ZM510 and ZM615 weight Indicators. These high performance, multi-function indicators provide the flexibility to be adapted to your individual requirements and are suitable for a wide variety of applications including dusty, wet or high pressure and heavy washdown environments. The ZM510 and ZM615 can display, analyse, store and transmit data across a range of technology methods to meet your specific installation.

Find Out More:

Ready to maximise your throughput and profits? Contact us today to schedule a demo and revolutionise your bulk weighing processes.

Product Resources

These resources help you get the most out of your Avery Weigh-Tronix product. Can't find what you're looking for? Contact Us

United States

United States  United Kingdom

United Kingdom  Canada

Canada  Canada (fr)

Canada (fr)  India

India  Malaysia

Malaysia  Ireland

Ireland