NSF and EHEDG – Hygiene product ratings explained

What is NSF approval?

NSF approved products have been designed and tested to a high hygiene standard, suitable for use within most food prep and processing applications.

NSF National Sanitation Foundation was founded in 1944 in North America to help provide guidelines and standards for food safety and food sanitation requirements. It is still being used and relied on within most food prep or food processing operations around the world. NSF ANSI 3-A marked products are tested to the higher NSF standard that guarantees the product can be safely used in direct contact with raw meats, pottery, and fish.

What is European Hygiene Engineering Design Group (EHEDG) approval?

EHEDG approved products have also been designed and tested to a high hygiene standard suitable for use within most food prep and processing applications.

EHEDG European Hygiene Engineering Design Group was founded in 1989 and is one of the leading sources of hygienic design and engineering expertise within the European food industry. They work closely with European food producers, processing companies, food equipment manufacturers, university research institutes, and public health authorities to help support and shape the future of food safety and quality within this industry.

European Hygiene Engineering Design Group (EHEDG) was founded in 1989 and is one of the leading sources of hygienic design and engineering expertise within the European food industry. They work closely with European food producers, processing companies, food equipment manufacturers, university’s research institutes and public heath authorities to help support and shape the future of food safety and quality within this industry.

NSF or EHEDG

NSF and EHEDG are two of the leading food safety federations used globally when it comes to food safety and sanitation. NSF is more dominant within North America where as EHEDG is more dominant within European countries.

Both these governing bodies follow very strict guidelines when it comes to food safety. Products that hold one of these approval markings mean they have been designed to their strict guidelines and have already been fully tested and evaluated by them to guarantee the products are safe to be used within a food prep or processing envelopment.

All the manufacturing plants that make products that hold NSF or EHEDG approval marks are also annually audited to guarantee that the products continue to be made to the highest food standards possible. Failure to do so will result in the NSF or EHEDG approval being removed from them.

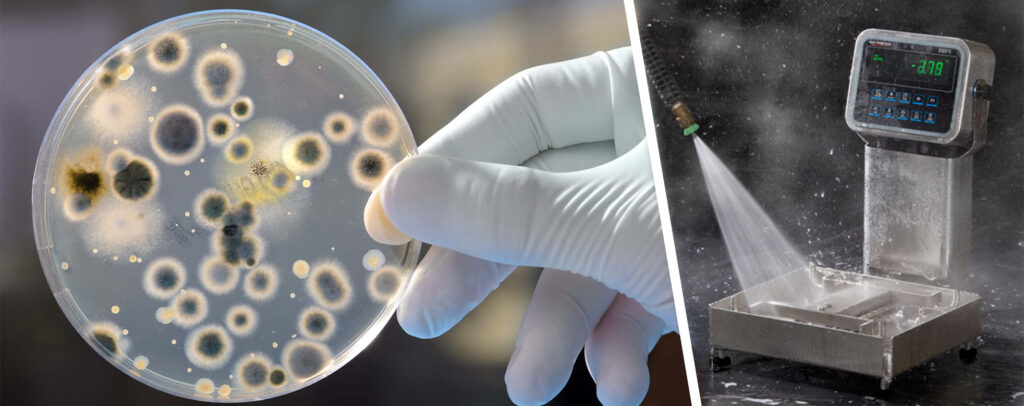

The products that have been fully designed for correct use within a food processing plant and marked with NSF or EHEDG have already been designed to make it easy to be cleaned with no hard to clean areas or have any unwanted built-in bacteria traps that can hold and harbour unwanted bacteria or bugs.

Why select a NSF or EHEDG certified product?

A lot of food processing companies look to buy equipment with one of these approvals as it gives them better peace of mind that it has been designed and built to the higher food grade standard. They have been fully evaluated by NSF or EHEDG deeming them safe for use within a food processing application.

Does all foods processing plant equipment have to be NSF or EHEDG approved products?

No, this is the responsibility of the food processing manufacturer to carry out their own risk assessments on all equipment used within their food processing area. Products that hold an NSF or EHEDG approval help to give plant and line managers the reassurance that the product has already been fully inspected by NSF or EHEDG and found to be safe for use within these food environments. Products without any of these markings must be evaluated to make sure they are also safe for use within their own food prep processing areas.

What are the main design points to look out for when purchasing new equipment that will be used directly with food substances?

NSF and EHEDG approved products have already gone through a strict product evaluation by them to guarantee that the product has been correctly designed to meet all their design guidelines, making them safe to be used in a food prep area.

Products without any of these food safety approvals need to be inspected closely for food or bacteria traps where food can easily be pushed into or trapped either when in use or during the cleaning process. Any hard to get areas risk trapping food partials that can then grow bacteria.

Another big consideration to look at is products with hard to clean areas, these can still be used but the clean down process will most likely take much longer to successfully get clean. This is a daily cost that can add up over time.

Example of Hard to Clean Areas

NSF & EHEDG approved products have been designed to eliminate and reduce many of these hard to clean areas, making the cleaning process fast and easy.

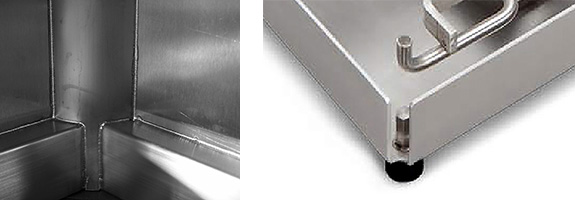

Sharp corners with no way to wash out food particles when cleaning can take longer to keep clean. Where possible, all corners should be rounded or have through holes to allow any food particles to be easily washed away when cleaning.

Avoid blind holes and hard to get to areas where food particles can easily get stuck and trapped. Scales with holes or gaps within the scale case housing that food or bacteria can pass though are not recommended as it stops the cleaning crew gaining full access to properly sanitise the product. Scales with fixed top weigh pans make cleaning harder to guarantee full food safety.

Most tabletop scales normally require holes in the top of the case to allow the weigh pan to weigh accurately. These holes also allow unwanted food particles and bacteria to get inside the scale.

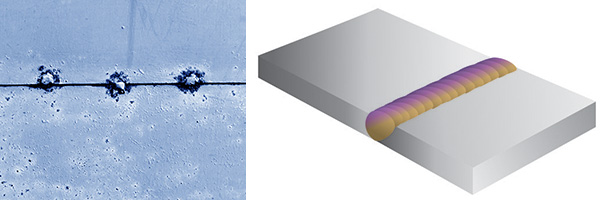

Spot welds and stitch welds are not recommended in food prep areas as food and bacteria can easily get trapped behind the plates and make it impossible to clean out. In a food processing area, it’s very important to have continuous welds that have to be ground smooth with no holes and imperfections to stop food residue or bacteria from getting trapped.

Unprotected threads: all threads need to be covered and must not have more than 1½ unprotected, uncovered threads visible.

Solid steel design is preferred over welded tubular framework. Tubular framework is not preferred in most food environments due to it being impossible to clean out the inside of the tube after welding. It is impossible to spot small holes and hairline cracks within the weld area that can easily harbor dangerous bacteria that can leach in and out of the crack over time.

304 & 316 grade food grade stainless steel is the preferred material to be used within most food prep areas due to its high corrosion resistant properties and its resistance to being scratched. Some plastics can be also used in food prep areas, but care is needed when using plastics to avoid getting deep scratches that can harbor bacteria.

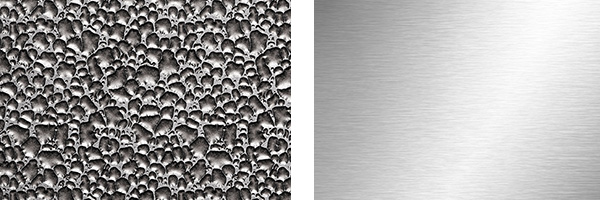

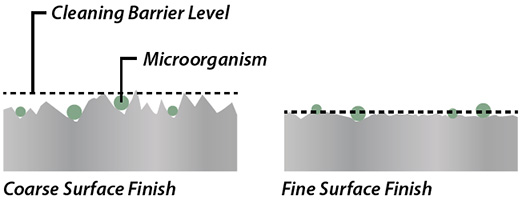

Smooth surface finishes over textured surfaces are preferred in most food prep applications. The finish of the scale surfaces, both inside and out, must be smooth and free from scratches as any scratched areas can easily harbor unwanted bacteria that is hard to clean.

Most stainless-steel food contact surfaces require a fine grain brush finish that is then pickled and electrically polished to provide a smooth surface that bacteria can’t hide on.

All Avery Weigh-Tronix food grade bench bases are finished with a fine brushed surface under Ra 0.8 μm, as specified in NSF/ANSI Standard 3-A 14159-1 -2010, to stop any microorganisms from taking hold and growing on the surface.

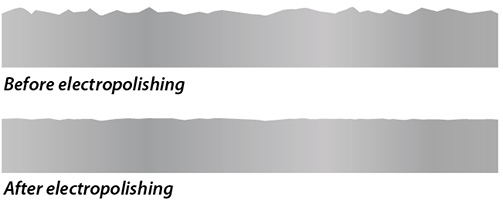

Why pickle and electropolish finished are preferred.

The main food areas where raw food comes into contact with the stainless steel, such as the weight platter and column, have surfaces that are normally subjected to a pickled and electropolished finish. This helps to remove any impurities on the surface of the stainless steel while smoothing and rounding the peaks found within the fine brush finish. This results in a finish that is much easier to clean and prevents bacterial microorganisms from growing on the surface of the scale.

United States

United States  United Kingdom

United Kingdom  Canada

Canada  Canada (fr)

Canada (fr)  India

India  Malaysia

Malaysia  Ireland

Ireland