Guide: Weighing in Food Processing Environments

Whether producing, handling, packaging or shipping, it is vital that each step of the food and beverage production process is accurately documented and accounted for. An electronic scale system can efficiently weigh and document product information, allowing manufacturers to monitor, trace and control production—and all materials involved—from start to finish.

To optimise processes, weighing equipment can be used at every step. From tracking incoming raw materials and inventory, to measurement of ingredients, quality control and shipping finished goods. As well as efficiently gathering, documenting and storing weight information, high-accuracy scales can increase revenue in these applications. This is done by reducing giveaway and ensuring customer orders are accurately invoiced and managed.

Legal-for-trade weighing

A scale system capable of legal-for-trade weighing is an invaluable asset in the food industry. Especially as revenue is commonly based upon the weight of commodities purchased or shipped. Legal-for-trade accuracy is required for business transactions where goods are bought or sold by weight. However, the benefits of a legal-for-trade system extend beyond legality. The legal-for-trade approval can also be seen as a badge of reliability. That is, proof that your scale can provide repeatable weighing of goods. This ensures customer satisfaction, precise billing and accurate inventory records.

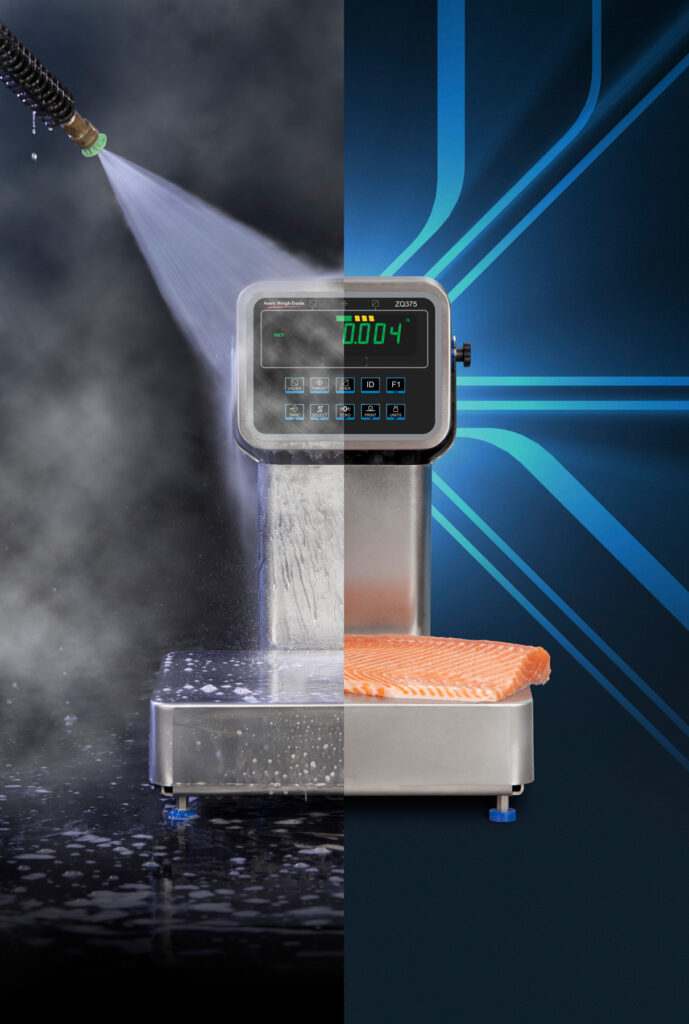

Hygienic weighing equipment

In today’s global market, maintaining a pristine environment is absolutely critical to the success of food manufacturers. It is important that companies manufacturing weighing equipment for the food industry ensure that the products they supply comply with best practices and meet strict legislative requirements. Many of our products are made specifically with the food industry in mind. With strict global approvals as well as IP washdown certification and NSF approved sanitary design, you can be assured that you’re working with a partner that understands the issues that are critical to your business.

Checkweighers

On a food production line, fast and accurate checkweighing can make a big difference to a company’s bottom line. Underweight packages can lead to unhappy customers, while overweight packages lead to costly giveaway and overweight shipments. Whether you need to spot check raw materials or finished goods or to ensure adequate quality control, our highly accurate checkweighers provide visibility of weighing data and statistics which can help to maximise performance and profitability.

Our food-grade, stainless-steel solutions have been specifically designed to meet the stringent hygiene requirements of the food processing industry. With an IP69K rating for heavy washdown environments and NSF to NSF/ANSI Standard 3-A, these robust checkweighers withstand even the most rigorous cleaning regime. The simple operator interface and easy-to-read display combine to provide a scale which is user friendly, yet fast and highly accurate.

Conveyor Scales

Where speed and accuracy can impact profitability, conveyor systems offer the ability to improve processing speed. This is done by reducing lifting and increasing throughput. The scale operates while the conveyor is in motion. It is intended for weighing individual boxes, cartons, cans or unpackaged products such as large cuts of meat. These simple-to-install electronic scales can easily integrate with computers, label printers and scanners for further process control.

Vehicle Scales

Properly managing inventory and billing in food processing environments depends upon documenting and weighing both inbound and outbound freight. Whether verifying load weights for incoming ingredients or shipping finished goods for ongoing distribution, accurate weighing is essential. With the high cost of fuel, bulk carriers also have to balance the need for optimal loading with safety concerns. Weighbridges, truck scales and axle weighing systems from Avery Weigh-Tronix will help ensure that both incoming and outgoing loads are weighed quickly and accurately.

Unattended terminals – For increased efficiency, weighbridge and truck scale controls may be integrated into a stand-alone console. This can then facilitate unattended weighing operations. Where allowed by local Weights & Measures, the terminals enable drivers to complete weighing transactions 24/7, without leaving their cab. The result is that your weighbridge or truck scale can run smoothly without a dedicated operator. This results in reduced operating costs, extended hours of availability and improved health and safety. This is done by allowing drivers to stay within their vehicles.

Digital Weight Indicators

On a basic level, weight indicators collect, store and communicate weight data. More advanced digital indicators use wireless communications to transmit data to back-office systems. This improves management information and control and producing instant, accurate invoices for all materials weighed.

These indicators can be linked to printers, bar code scanners, computers and other peripherals. This is for integration into existing networks, allowing effortless data transfer and management from anywhere in the operation. Whether you require fully programmable indicators capable of complete process control or stainless steel, IP69K rated indicators for use in heavy washdown environments, we have a model to suit.

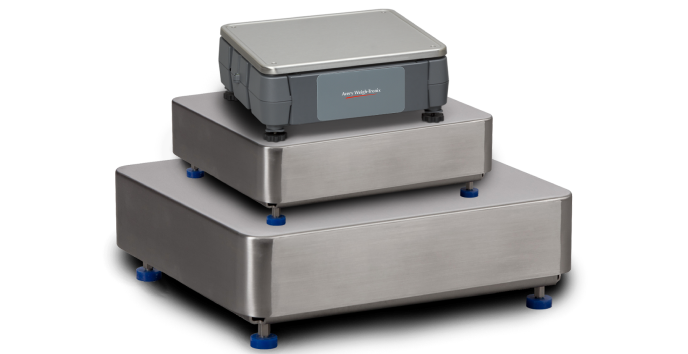

Bench and Floor Scales

Used mainly when shipping or receiving or when sorting inventory, bench and floor scales are capable of weighing goods with very high accuracy, reducing the likelihood for revenue loss. Often found within a food warehouse or ingredient store, both bench and floor scales are available in stainless steel. This is for food processing environments where heavy washdown and strict sanitation is required. The scales also come in mild steel for warehousing or goods in/out applications. Such applications for when an operator might set palletised loads or totes on to a floor scale using a forklift.

Forklift Scale

A forklift scale allows drivers to lift and weigh bundled materials on the truck. This expedites operations by enabling forklift drivers to take raw ingredients directly to storage upon delivery. Or even packaged goods to dispatch while tracking the weight, origin and storage location during transport. This process results in real-time data acquisition which can be used for billing and inventory management. The ability to transport and weigh materials in one simple step results in tremendous time savings and a speedy return on investment. Optional in-cab instruments such as bar code scanners allow forklift operators to instantly capture all necessary freight data available and then transmit this information with weight data wirelessly via Bluetooth® or radio to supervisory computer systems.

Software

Avery Weigh-Tronix scales can be paired with sophisticated software and indicators to provide additional data collection, tracking, analysis or ingredient control. Software innovations help to facilitate efficient documentation and management of key weight, commodity and scale data, all of which can be vital for traceability. Whether you need a simple data capture package, an integrated management system monitoring operations and first in/first out inventory in real-time or a solution which can automate batch and recipe control, we can supply a standard or tailor-made solution to suit

Process Integration

We can integrate scales and software into your existing network and, with local or remote access, you can easily monitor operational performance. Systems range from applications to monitor a specific function to fully-integrated solutions for management control across your food processing operation.

Scale Calibration, Service and Maintenance

Having a trusted and reliable service supplier can keep your business moving and maximise ‘up-time’. We are committed to providing high quality, lifetime service support for all of our weighing equipment. Avery Weigh-Tronix is supported by a global network of dedicated technicians on hand to install and maintain your equipment, including regular calibration, maintenance, servicing and repair. Focusing on regular preventative maintenance keeps your equipment working at maximum efficiency and reduces the likelihood of costly emergency breakdowns which can halt production. Highly trained service technicians will work with you to identify potential issues before they arise to ensure that your equipment is running reliably and accurately. We will ensure that your equipment is both accurate and compliant.

United States

United States  United Kingdom

United Kingdom  Canada (fr)

Canada (fr)  India

India  Malaysia

Malaysia  Ireland

Ireland