Weighing Up Traceable Consistency for Whisky

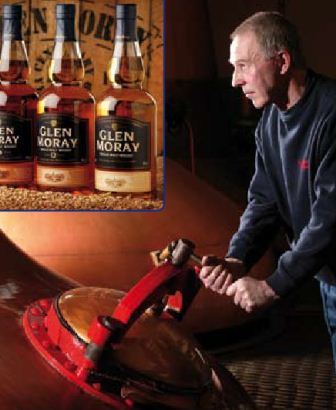

A weighing system from Avery Weigh-Tronix has helped improve production efficiency and quality for Glen Moray’s Scotch whisky distillery. It measures batches of malted barley to an accuracy of 99 percent and provides traceable data to monitor production and to meet the requirements of Customs and Excise.

In common with all scotch whiskys only three ingredients are used; malted barley, water and yeast. The most expensive and important ingredient in the process is the malted barley. In addition, the Glen Moray distillery has to provide accurate and traceable records of the malted barley used to Customs and Excise.

Weight data vital to production efficiency

Says Graham Coull, distillery manager: “The price of barley is now very expensive so we must extract the maximum amount of sugar from it for fermentation. We need an accurate and reliable weighing system to ensure that we can monitor efficiency. Malted barley can vary in character from batch to batch so it is essential that we have accurate information about exactly how much of each batch we are using.“

Less reliance on manual systems

“The Avery Weigh-Tronix system also means that we don’t need to rely on manual records and paperwork. It is faster and easier for the operative to use with no chance of error. It helps us to become more efficient and concentrate on other areas to improve our whiskey.”

An Avery Weigh-Tronix programmable indicator controls the system. This collects and records data and can interface with a PC and other software applications.

United Kingdom

United Kingdom  Canada

Canada  Canada (fr)

Canada (fr)  India

India  Malaysia

Malaysia  Ireland

Ireland