A simple step towards reducing driver detention costs

Driver detention is such a hot topic for everyone in freight and logistics, and rightly so.

It has an impact on the carrier, the driver and the customer. And it appears to be gradually getting worse, with delay lengths of over 2 hours increasing by 2.8% every year and by 6.9% on delays of over 6 hours. Alarmingly, this detention is costing the trucking industry over $1 billion a year in foregone profits.

So, what can be done about it?

It’s easy to say that if shippers and receivers planned and organized better, communicating more with the carriers and drivers, then life would be easier. This sounds great. But what are the practical actions that can be taken to start making this issue better?

We’ve identified automating certain parts of the drivers journey at the loading/unloading facility can not only speed up throughput, but also improve labor efficiency.

What is driver detention?

Driver detention is when a driver and route is delayed for more than 2 hours at the time of pick up or delivery. Over this 2-hour ‘free time’ period, a detention charge is applied to compensate the driver and carrier for being held up. The detention charge is usually between $35 – $75 per hour.

Frustratingly for almost all involved, the detention usually results in the driver running out of legal driving hours, missed appointments, and potential loss of further loads and loss of revenue for both carrier and driver.

Most trucking companies won’t pay for driver time waiting, only if it exceeds 2 hours. Even then it might only be an hourly rate of around $15. With many owner-drivers operating $100k+ truck investments, it’s not profitable for anyone to wait around for $15 per hour.

Currently, commercial motor vehicle (CMV) drivers can be on-duty for a maximum of 14 hours. Only a maximum of 11 hours can be spent driving. There are several factors that can affect a drivers’ hours of service, but none more than detention at a customer’s facility.

A problem that’s out of the driver’s hands

An average veteran CMV owner-driver will only drive for 6.5 – 7.5 hours per day, well under the 11-hour driving limit.

They’ve been driving for years and have a tight schedule to keep. They know how to avoid getting delayed by traffic, bad weather and accident hotspots.

They can turn up on time for their appointment, but then get delayed for hours, usually at their own expense.

They are then late delivering their load, miss the rest of that day’s appointment times and run the risk of hitting their Hours-of-Service limit.

A common comment made by drivers and shippers in surveys carried out by The American Transportation Research Institute (ATRI), describe customer facilities to be constantly understaffed. The comments talk about slow loading and unloading, with preloaded trucks not being ready by the time of the scheduled appointment. In some cases, drivers have had to wait for products to finish being manufactured.

Drivers also commented that shippers and receivers overbook appointments to keep their own operations efficient, but at what cost?

A driver turns up for their appointment and is greeted with a long line of trucks in front of them, waiting for space or a dock to be made available. If the wait time is over 2 hours on their electronic logging device, the carrier and driver will need to be compensated.

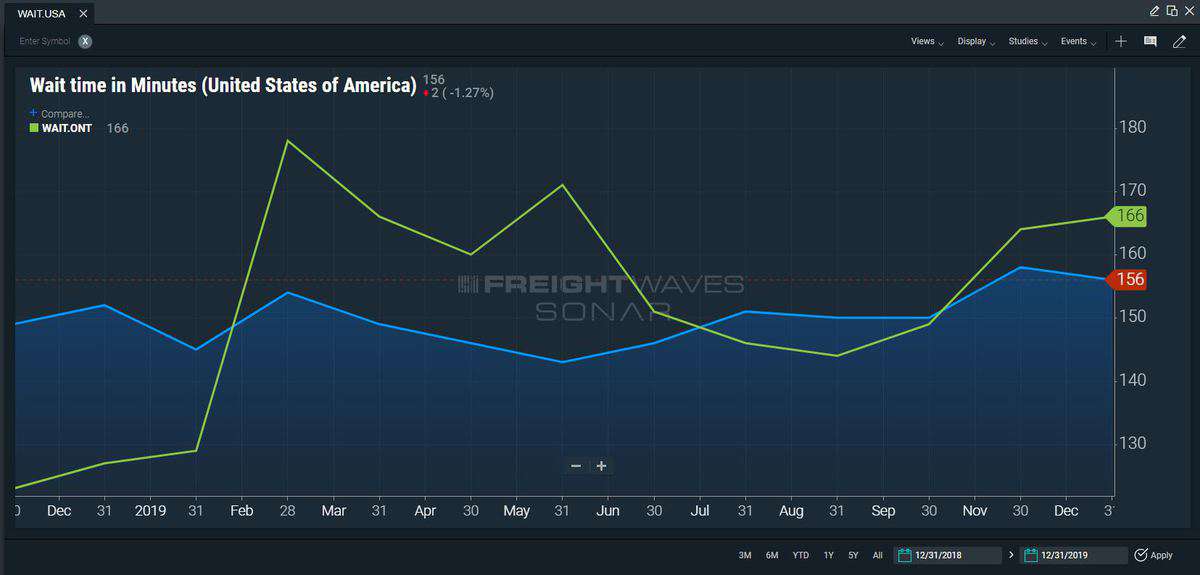

These common issues lead to an average wait time of 156 minutes, with the average slightly higher in California.

Chart shows the national detention time of 156 minutes as of Dec. 31, 2019, compared to detention time of 166 minutes in Ontario, California.

If we could only reduce the wait time by 30 – 40 minutes, theoretically we could drastically reduce the $1 billon a year in foregone profits and put some efficiency and profitability back into the truckers’ pockets.

Could it even help with the side issue of attracting and retaining qualified truck drivers? Possibly!

Effects of driver detention on safety and productivity

The excessive delays caused by driver detention have a direct impact on driver productivity. When detained, drivers lose on-duty, revenue generating time.

Not getting loaded on time will make a driver’s tight schedule even tighter, forcing them to be late for further appointments throughout the day. Late deliveries and missed pickups will also have influence carriers’ future business opportunities, potentially losing out to competitors.

Beyond the hassle of a delay is driver safety. With the impact on a truck driver’s hours of service in mind, they are more likely to drive faster and take risks to claw back some time and meet scheduled appointments. The temptation to continue driving outside of their allotted hours is greater and may be linked with increased accident risk.

So, how do we practically improve efficiency and minimize driver detention?

Over 60% of carriers surveyed are calling for better organization and communication with shippers and receivers. Part of the problem is a lack of understanding of hours of service regulations.

Improving awareness of issues as a result of driver detention would go a long way to helping the situation improve, providing better scheduling, keeping of appointments and enough staff and equipment to do what’s required.

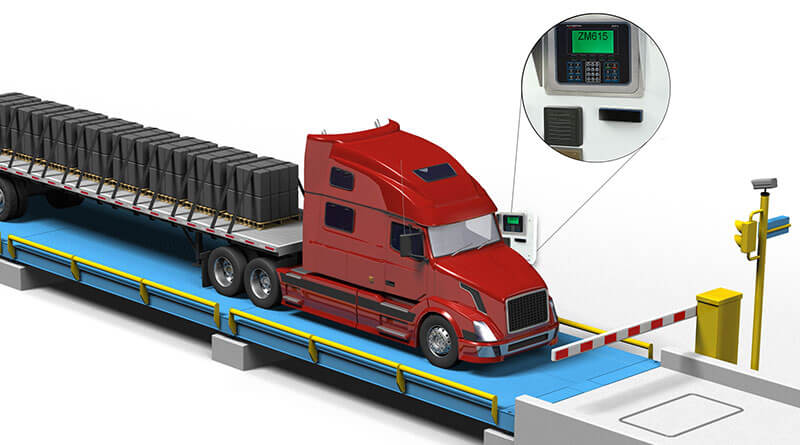

For facilities that must weigh trucks in and out, there’s a simple solution that can help speed up processing trucks, getting them loaded and on their way quicker.

Traditionally a truck scale may have one or two dedicated operators that identify trucks and match them to appointments, organize the flow of trucks through the facility, weigh each truck and provide a ticket to the driver.

All these transactional tasks can be streamlined by automating the truck scale with an unmanned kiosk system.

A relatively small investment in technology, not only allows managers to reduce or reallocate costly labor, but helps improve safety, efficiency and transactional accuracy too. An unmanned kiosk system keeps truck scales operating smoothly, speeds up truck throughput and that means less time waiting at customer facilities.

There’s no denying the contributing factors to driver detention and the cost implications that come with the problem. Is there something you can do to help reduce the costs for all?

United Kingdom

United Kingdom  Canada

Canada  Canada (fr)

Canada (fr)  India

India  Malaysia

Malaysia  Ireland

Ireland